Fluid management

Mechanisms

Structural parts

for electric vehicles

Flagship product

The Flush

handle

Attractive, aerodynamic, light, safe – the Flush handle is a revolutionary new approach to exterior opening controls.

Concentrated product innovation, produced exclusively for Renault. AKWEL expects to manufacture 600,000 units by 2025.

42 assembled components

for 1 handle.

Design & prototyping

Vigo, Spain

Electronics and software

Romans, France

50 staff

active on the project.

Production

Vigo, Spain

The life cycle

of a product

Project launch & market analysis

In-depth market analysis to identify weak signals and promising trends. Next, formation of the team, establishment of goals and schedule, risk analysis, industrial master plan.

Prototyping

Design of a prototype, component specification and prototype validation. In the case of the Flush handle, the initial design and concept validation work were conducted via a co-innovation process with Renault teams between 2015 and 2018.

Design & development for mass production

Final product design (3D modelling, component architecture, plans, risk analysis, digital simulations) and manufacturing processes, followed by validation of first developments. For the Flush handle, this phase featured a 50-strong multidisciplinary team to tailor the handle's design to the first car model to which it was to be fitted. More than 60 digital simulations were conducted for this final design phase.

Pre-production

Validation, design and calibration of machine tooling, production/assembly lines and the manufacturing process Product testing and metrology ahead of final validation for the start of mass production. In the case of the Flush, there was further innovation in the assembly lines, which are fully automated and robot-controlled. More than 250 different tests were conducted (extreme temperatures, resistance to force, 120,000 opening/closing operations, etc.).

Manufacturing

Assembly of components on the assembly line, automatic inspections, traceability, packaging and delivery. For the Flush, 30 robots work in synchronisation to produce the part, and each part is individually traceable.

And after that?

Once delivered, AKWEL products start a new life cycle. They are fitted to the vehicle, inspected one last time, and then used by the driver until the end of the vehicle’s life.

Although AKWEL is not in control of the future of its parts, the group designs them from the outset with recycling in mind.

- Where possible, materials that can have a second life and be recycled are used.

- Component weight and size are minimised to reduce the quantity of materials used in manufacturing and the vehicle's consumption of resources while in use.

- Lastly, by making sorting easier:

for example, the Flush handle is weld-free, and can therefore be easily dismantled at a recycling centre.

It is estimated to be 95% recyclable.

R&D AND INNOVATION

" The ‘golden path’ of innovation is to discover products that have no equivalent in the marketplace. But there’s another path that’s just as effective: process innovation, which consists of developing more efficient or less expensive manufacturing processes.

AKWEL’s secret is not having to choose between these two paths. "

— ANDRÉ COUTIER, President of AKWEL’s Supervisory Board

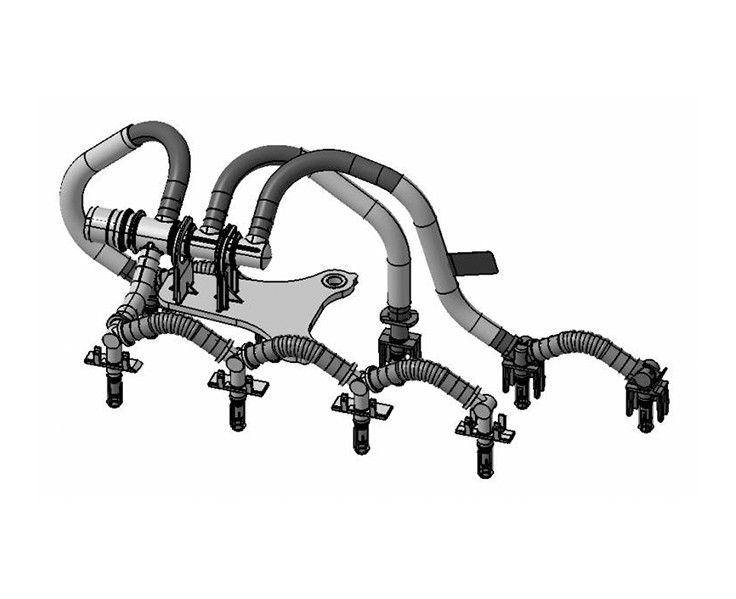

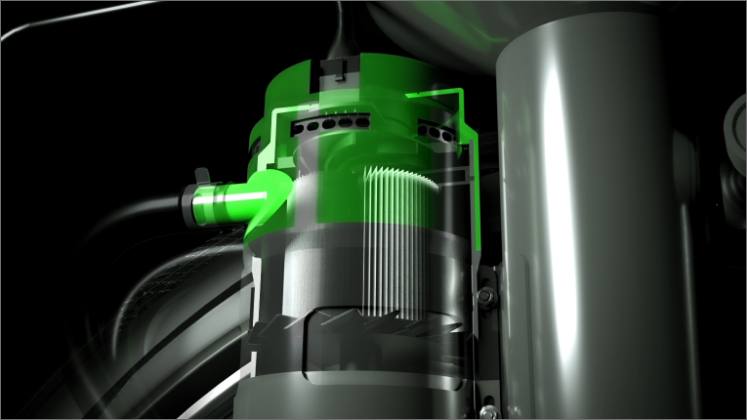

EV2020 Project

A thermal battery management system

developed for Renault's Megane E-Tech – the cooling system plugs directly into each side of the battery, offering a solution that saves considerable space and weight.

An innovation driven by customer demand, focused on technical/economic solutions.

2 patents

A short history

This solution was developed specifically for the Megane E-Tech, an electric car from Renault, produced in Douai in line with a “made in France”-driven philosophy, using products developed by French equipment manufacturers. AKWEL worked to address technical issues faced by its customer. The patents were filed as part of the solution-seeking process in a highly applied process.

AKWEL added value

The technical-economic aspect. “Electric batteries only work well if they are at the right temperature; neither too hot, to avoid safety risks linked to overheating, nor too cold, to avoid excess consumption. Our system keeps batteries at their optimal temperature while maintaining an attractive balance between technology and economics; that’s what made the difference.” Thomas Gaye, AKWEL’s Innovation Manager.

The Flush handle

A futuristic handle for electric cars;

a concentrated package of technologies featuring an aerodynamic, secure and attractive design – Hidden in the door, the Flush handle pops out automatically and unlocks the car as the driver approaches. The whole operation is virtually silent.

An innovation born of intuition, perseverance and anticipation of customer needs.

6 patents applied for, out of a total of 18 inventions patented during its development.

A short history

10 years of development were required for our flagship product. It started when AKWEL decided to focus on niche handles, involving a greater degree of innovation to ensure greater differentiation. The Vigo team started work on a new generation of handle. The project remained hush-hush for a long time, but their tenacity paid off: the first customer presentation was an immediate success, and the Flush handle was co-developed with Renault.

=> From 2023 onwards, AKWEL will be producing 300,000 parts/year to equip the Renault Megane E-Tech.

AKWEL added value

Aerodynamics and marketing value. “People buying electric vehicles are buying a car of the future which is less harmful to the planet. They want that to be obvious to others. This handle symbolises that desire: it's something new for AKWEL, which is well used to “hidden” parts. Thomas Gaye, AKWEL’s Innovation Manager.

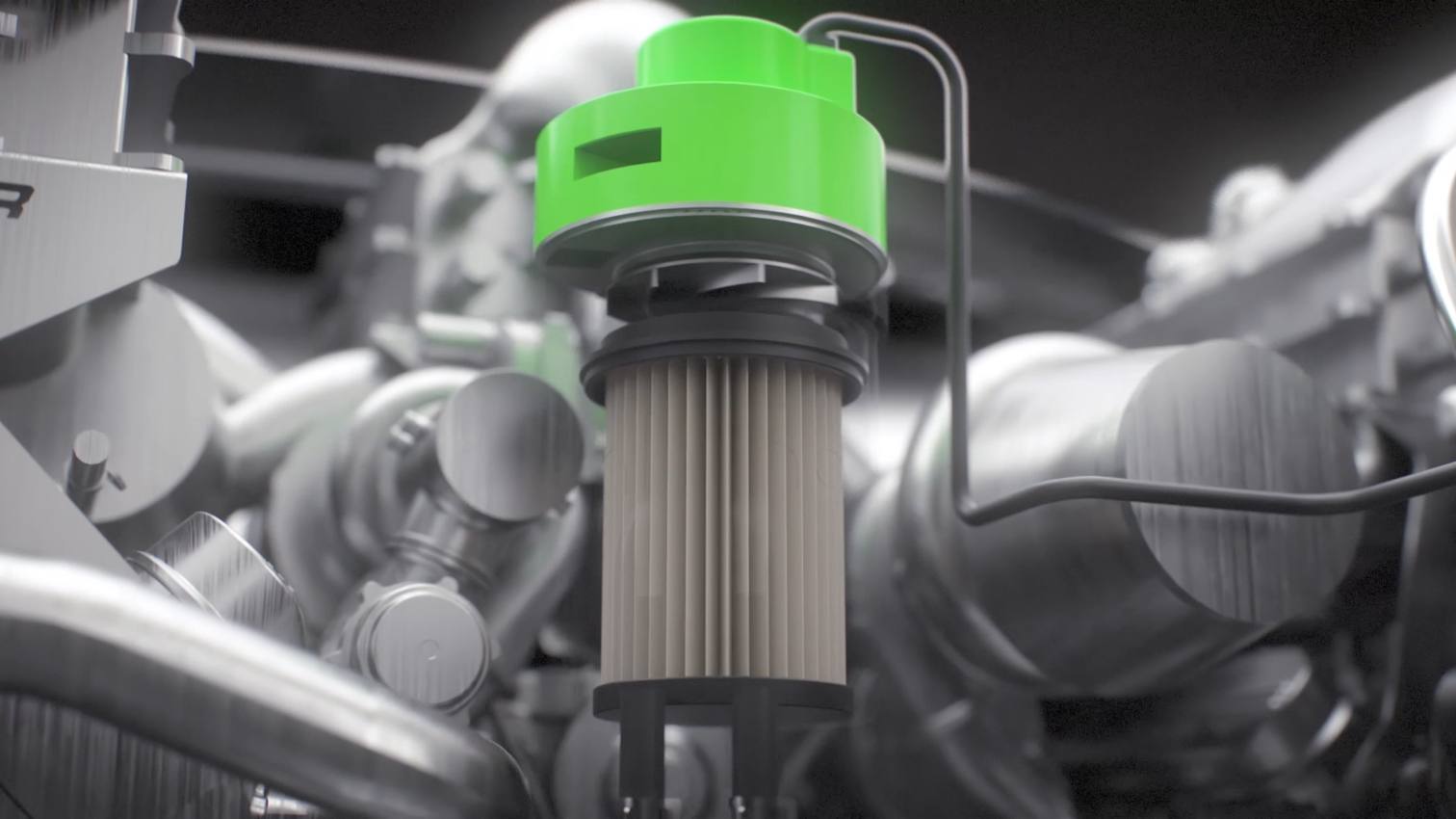

The SCR tank

A nitrogen oxide (NOx) treatment system

including an additive tank and an injection pump, radically simpler and smaller than competitors’ solutions – For this product, AKWEL has drawn upon its expertise in mechatronics.

This innovation is driven by regulations and new standards for diesel vehicles.

4 patents

A short history

This product was developed in just 5 years! Originally arising from a request from the manufacturer Stellantis in response to changes in regulations, it represented a turning point for AKWEL. Stellantis was looking for a solution relating to injection of the ammoniated additive for transforming NOx gases into water vapour and nitrogen inside the exhaust. The clever new idea? Combining an injection pump with a tank where the additive is stored under pressure, offering a disruptively lower price than the competition, thanks to a much smaller pump.

=> The AKWEL SCR system is now fitted to a large part of the Stellantis diesel vehicle fleet in Europe.

AKWEL added value

Simplicity. “Innovation is often associated with complexity. But in fact, innovation often means offering something simpler, stronger, more reliable and easier to transform and manufacture.” Thomas Gaye, AKWEL’s Innovation Manager.

Tamic©

A brand-new solution to capture fine particles

emitted during braking, developed by the Tallano Technologie start-up in partnership with AKWEL – This brake pad-based suction and storage technology reduces particulate emissions by 85-90%!

In this partnership-driven innovation process, initial research is conducted by a start-up, and the final development and mass production phases are handled by AKWEL.

Several patents filed by Tallano

A short history

AKWEL’s partnership with a start-up is indicative of the general trend towards innovation: as they grow, groups like AKWEL are joining forces in support of their R&D efforts. The principle is a simple one: to identify good ideas in response to identified issues, and to provide an industrial foundation for moving from concept to mass production.

AKWEL added value

Environmental impact. “This collaboration is enabling the development of a new line of automotive pollution control products at the forefront of the fight against fine particulate emissions – an issue we have been working on for many years. With Tamic, we are able to offer a more innovative solution to our customers.” Mathieu Coutier, President of AKWEL.

Partnership AKWEL x TALLANO